|

Reprinted with permission from ELECTRICAL LINE May/June 1999

A revolutionary new windpower generating technology that may be adding a different face and footprint to this rapidly growing renewable energy source is on the brink of commercial introduction. The new technology WARP™ - Wind Amplified Rotor Platform - developed, and recently patented internationally by ENECO of West Simsbury, Connecticut, is now at the point of licensing and/or commitment in various fields-of-use and geographic locations around the world.

WARP was developed by ENECO's founder, Alfred L. Weisbrich, an aeronautical engineer with many years experience in advanced rotors for fixed and rotary wing aircraft. He was also involved in the development of large conventional and vertical axis wind turbines for the aerospace industry, including the first vertical axis turbine at Kaman Aerospace for Sandia Laboratories, and the development of the world's largest capacity 4,000 kilowatt turbines for the U.S. Department of Energy/NASA.

WARP was developed by ENECO's founder, Alfred L. Weisbrich, an aeronautical engineer with many years experience in advanced rotors for fixed and rotary wing aircraft. He was also involved in the development of large conventional and vertical axis wind turbines for the aerospace industry, including the first vertical axis turbine at Kaman Aerospace for Sandia Laboratories, and the development of the world's largest capacity 4,000 kilowatt turbines for the U.S. Department of Energy/NASA.

Out of this aeronautical and aerospace background came WARP's wind amplifier module design that speeds up the wind with a velocity amplification factor (VAF) in excess of 1.5 over free wind. With the cubic effect of wind speed on power output, this amplification factor means that an increase of 65% in wind speed would result in a 450% increase in power.

The aerodynamically designed toroidal-shaped amplifier modules are vertically integrated on a core tower, in

building block fashion, allowing the system to be packaged to any power size from utility to commercial or village power scale. For large capacity systems, each module has two rotors, typically 2-3 metres in diameter. WARP's panelized design also lends itself to the piggybacking of photovoltaic cells on its structure, thus making it possible to add 10% more power

through the use of WARP as a combined wind/PV power system.

Mr. Weisbrich said WARP is not intended as an "us (renewable) versus them (fossil)" power system. He said, "WARP is designed so it can also operate as a stand-alone system with fossilfired power plants such as gas turbine, micro-turbine or diesel, housed in the tower base - and reduce fuel consumption and pollutants from 50 to 70 percent. We see WARP as a complementary technology with excellent economy - and environmentally 'green' characteristics to serve a variety of markets."

A $1.5 million expenditure on research and development through Rensselaer Polytechnic Institute (RPI), under New York State Energy Research (NYSERDA) support, as well as with prospective licensees testing WARP for various fields of use, has resulted in a convincing data base for the WARP technology. In addition, independently sponsored research has been conducted overseas, including computational fluid dynamic (CFD) analyses at the Technical University, Graz, Austria, and, recently, wind tunnel tests in Denmark. The results corroborated those generated by Rensselaer's scale model wind tunnel tests. With reference to the Graz CFD tests, it was also noted that tallstacked arrays of WARP modules would produce a VAF of 1.7 to 1.8 on average of the free stream wind speed, resulting in a relative maximum power of approximately 5 times that of the free air turbine.

A pre-prototype test of a WARP unit yielded significant data but unfortunately the results were limited because of a force majeure 100 year storm. On the positive side, although the storm destroyed all the costly and complex customized test instrumentation, including the on-board computer data acquisition equipment, it did not significantly damage WARP's modules and turbines. Depending upon site wind and module height, each WARP rotor is capable of, generating lOkW to 50kW by small, conventional high efficiency horizontal axis wind turbines at rated wind speed. WARP's modular system makes it is possible to tailor its power capacity from kilowatt levels to multi-megawatt levels without the need for costly rotor redesign and retooling. Plus, with the coincidence of optimum rotor rpm matching generator speed, the need for gearboxes in the WARP system is also eliminated.

A pre-prototype test of a WARP unit yielded significant data but unfortunately the results were limited because of a force majeure 100 year storm. On the positive side, although the storm destroyed all the costly and complex customized test instrumentation, including the on-board computer data acquisition equipment, it did not significantly damage WARP's modules and turbines. Depending upon site wind and module height, each WARP rotor is capable of, generating lOkW to 50kW by small, conventional high efficiency horizontal axis wind turbines at rated wind speed. WARP's modular system makes it is possible to tailor its power capacity from kilowatt levels to multi-megawatt levels without the need for costly rotor redesign and retooling. Plus, with the coincidence of optimum rotor rpm matching generator speed, the need for gearboxes in the WARP system is also eliminated.

In pointing out some of the system's other advantages, Mr. Weisbrich said that with WARP's higher energy capture capability, and small unit spacing because of shortened perturbation from its smaller rotors, a WARP wind farm would need on average about 1/4 less land per kilowatt of energy generated and also be able to use much taller structures than possible with conventional systems. Some other features mentioned by Mr. Weisbrich were WARP'S lower noise, no electromagnetic interference, absence of gear boxes enhancing reliability and the avoidance of pollution from hydraulic

and transmission fluid leakage, substantial fuel savings when integrated with fossil fuel plants in a stand-alone system,

and less danger to birds.

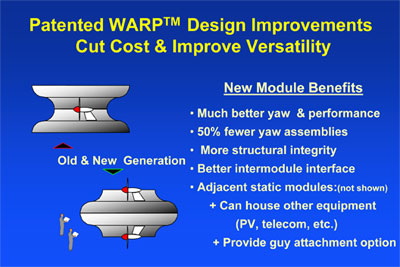

Preliminary applications systems, engineering designs and analyses were also prepared, along with detailed independent cost estimates and application cost-of-energy (COE) calculations. According to Mr. Weisbrich, projected COE was in the $.02 to $.04/kWh range but with recent research findings and patented design improvements, the WARP COE is projected even lower.

Mr. Weisbrich sees WARP applications ranging from traditional utility scale wind farms and distributed commercial or village power units, to cost-effective dual-use applications such as wireless telecommunication towers, electric power transmission/distribution towers, high-rise building integrated WARP 'penthouse' units, and offshore petroleum industry platforms.

|